Auxiliary axles

History Truck & Bus Activities

For many years VDL Weweler, as manufacturer of parabolic trailing arms, supplied air suspension systems to Phoenix Truck and Trailer Equipment in the UK. They were one of the leading manufacturers and suppliers of auxiliary axles for trucks, mainly for the UK market.

In the 1990's a customer specific mid axle air suspension was designed for Phoenix with special axle clamping to accept the 3 bend axle beam for pusher/mid axle solutions. These pusher axles have a special cold formed drop without welding. This shape was patented by Phoenix and VDL Weweler recognized the benefits of this unique axle shape. In 2004 VDL Weweler took over the intellectual property of Phoenix and started the supply of complete solutions for the Truck & Bus market sector and now are delivered worldwide.

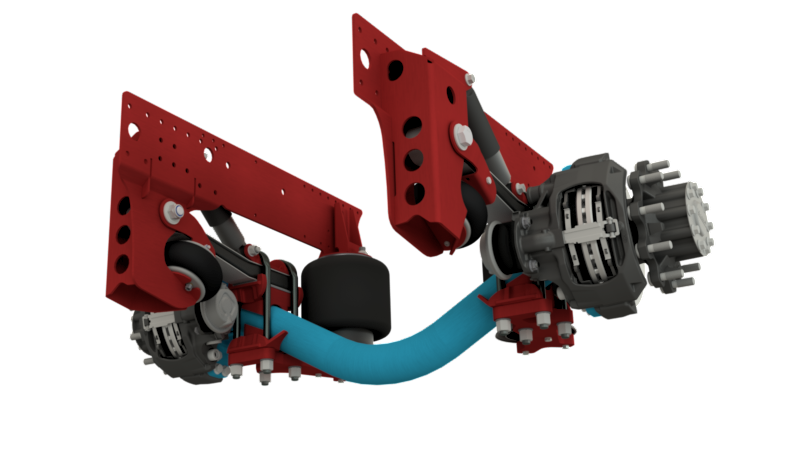

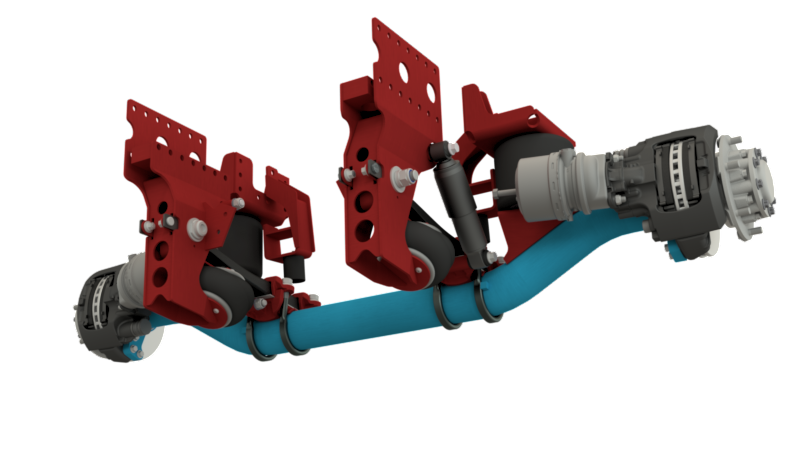

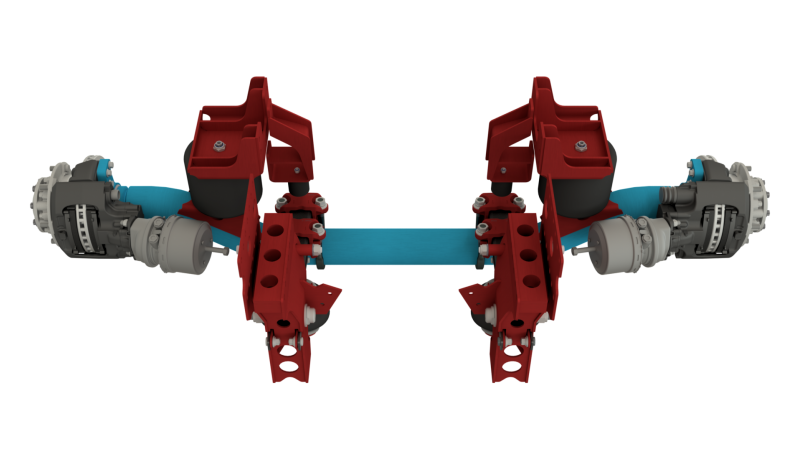

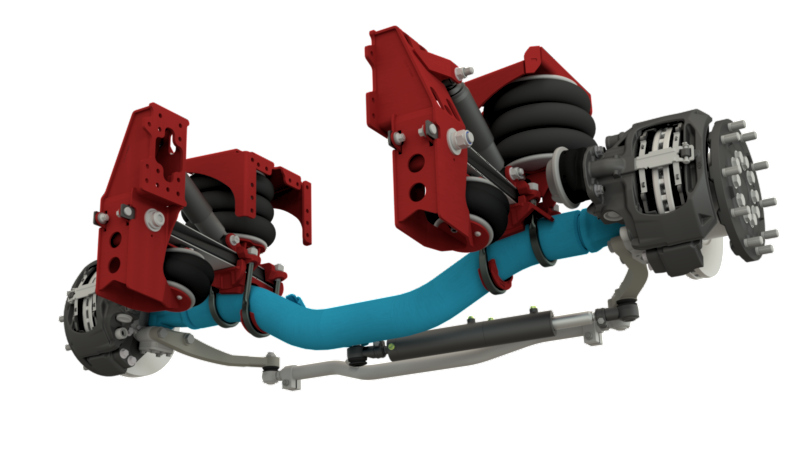

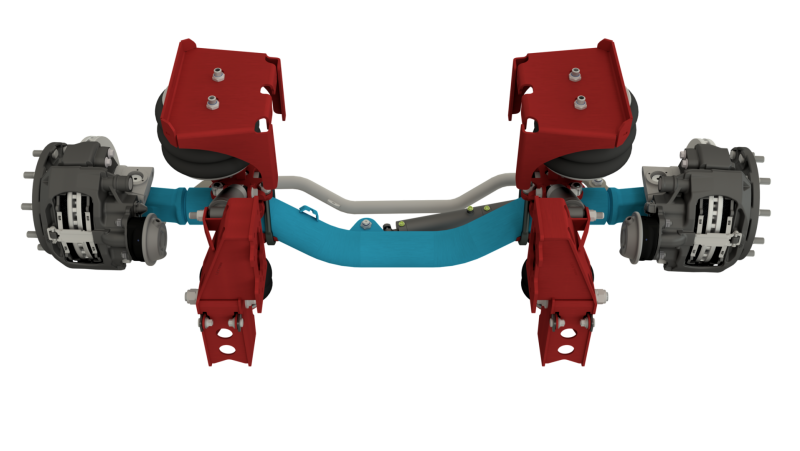

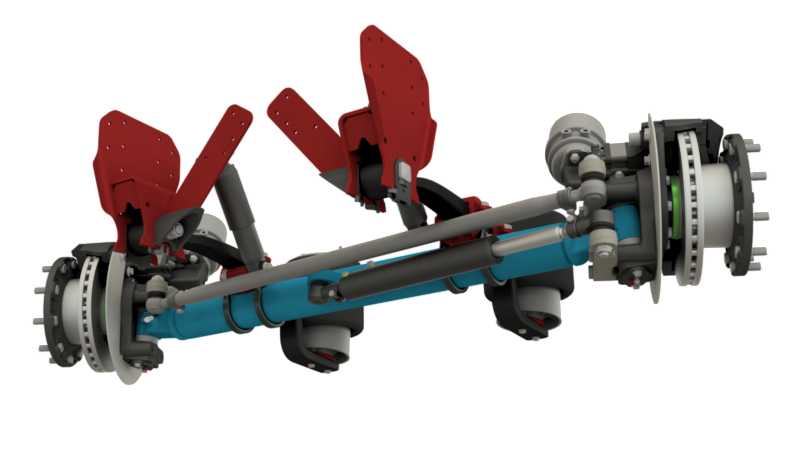

Currently VDL Weweler offer several designs of auxiliary axles as pusher and tag axle solutions, steered and non-steered. The solutions as shown below are completely pre-assembled with axle, suspension, wheelends and brakes. Optional electronic steering system or twin axle lift system are also available. .

Range of Auxiliary Axles

All VDL Weweler Truck & Bus auxiliary axles benefit from Ø127mm axle beams. The axle beams are gradually formed and torsional stiff, ideal for combining with VDL Weweler two bag air suspension solutions with flexible trailing arms. There is no requirement for anti-roll bars or panhard rods. This results in a light weight solution with only two pivot points which also contributes to simplified axle alignment. The position and depth of the axle drop is optimized for each application. The axle track and load capacity are application and customer specific. Wheelends and brakes are customer specific and standard OEM components can be integrated.

VDL Weweler wheelend components are available as an option: 17.5”, 19.5” and 22.5”. Axle load design capacities range from 4 to 10 Tons.

All solutions are equipped with customer specific VDL Weweler air suspension systems and can be equipped as an option with an integrated lift device.

Steering systems are ETS (electronically controlled and hydraulically powered) meaning no mechanical linkages are required.

Download Truck & Bus Flyer

SK Range

3 Bend axle beam - Non steered

The SK axle is used as pusher (mid) axle in front of the drive axle. Axle track and drop are customer specific.

This SK axle shape gives clearance to the prop shaft as well as the chassis rails. This axle will accept most offsets and angles of Driveline. Also compatible with certain designs of electronic drive motors.

Example:

Exclusive for DAF CF75 and LF55 FAP lifting pusher system.

- Equipped with DAF OE 22,5” twin tyre wheelends and brakes.

- Released for 10 ton axle load.

This robust twin leaf air suspension solution gives sufficient stroke with this model of axle beam for optimum axle lift. This design of axle and suspension allows for overload.

There is no need for an antiroll bar or panhard rod. This gives extra clearance around the chassis. The axle alignment is realised in the hanger brackets.

The lift device is integrated within the hanger bracket and therefore compact.

This design is suitable for LF as well as CF models. Also compatible with short wheelbase tractor units.

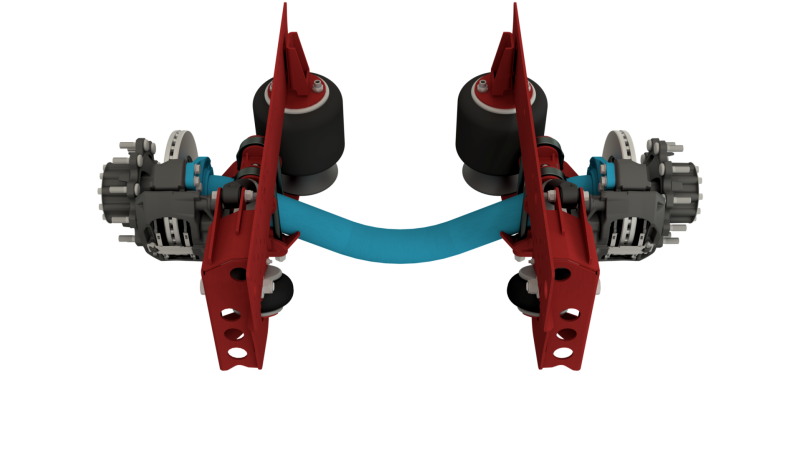

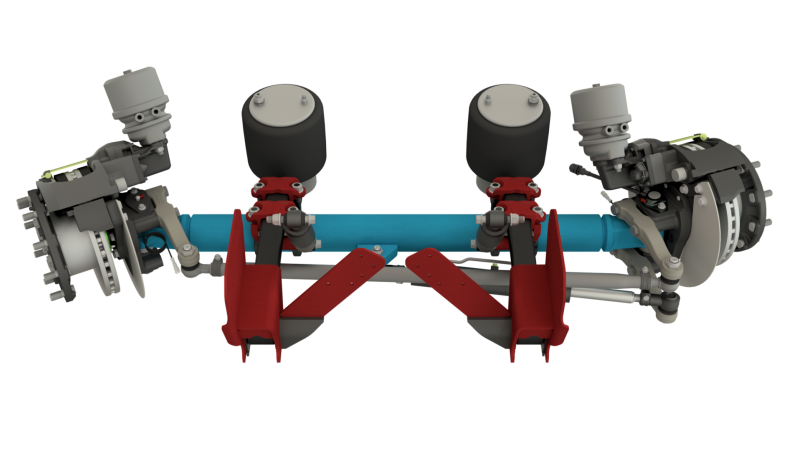

SKS Range

3 Bend axle beam - Steered

The SKS axle is used as a mid-steer pusher located in front of the driven axle.

The design can also be applied as a tag axle when the engine is located at the rear of a chassis.

Both wide and narrow track options are available as a complete solution.

Example

Dennis Eagle Mid Steer

- Wide and narrow track installations.

- ETS steering, no mechanical linkages.

- Modular design (most components are identical to the Dennis Eagle tag axle solution)

Specification VDL Weweler Wheelends:

- 22.5” disc brakes.

- Design capacity 10T.

- Choice of angle positioning of brake calliper (bolt on torque plate).

- Knorr Bremse SN7000 series brake calliper, alternative radial position.

- Bolt on steering arms.

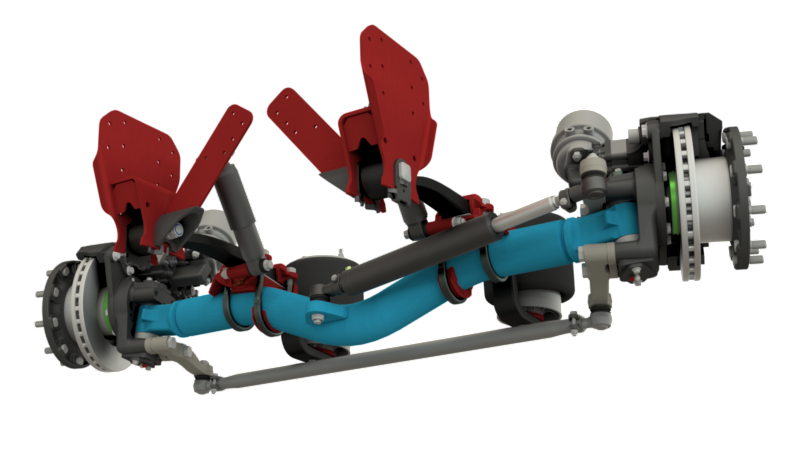

ST Range

4 Bend axle beam - Non steered

The ST axle shape gives possibilities of extra clearance for the chassis rails in case of a lifting tag axle in combination with a mechanically suspended drive axle.

This shape is also used as a 17.5” pusher axle.

Example:

Exclusively designed for a car carrier chassis from a large European truck manufacturer.

4.5T capacity lifting pusher axle.

OE 17.5” wheelend equipment.

STS Range

4 Bend axle beam - Steered

The STS Axle shape allows for extra clearance from the top of the axle beam to the underside of the chassis rails in case of a lifting tag axle.

The desgin can also be used as a second steer axle to give clearance to gearbox or engine an is also compatible with positioning and applications using electronic drive motors.

Example:

Iveco Stralis / S-way

- Design capacity 10T.

- Wheelends of choice

SRS Range

Straight axle beam - Steered

As the swivel of the VDL Weweler wheelends benefit from an offset of 69mm in relation to the axle beam centre line, a straight axle beam can be used in case of tag axle applications.

As the swivel of the VDL Weweler wheelends benefit from an offset of 69mm in relation to the axle beam centre line, a straight axle beam can be used in case of tag axle applications.

Example:

Dennis Eagle 8T Tag steer axle installation.

- Wide and narrow track installations.

- ETS steering, no mechanical linkages.

- Modular design (components have synergy with the Dennis Eagle tag axle installation).

Specification VDL Weweler Wheel ends:

- 22.5” disc brakes.

- Design capacity 10T.

- Choice of angle positioning of brake calliper (bolt on torque plate).

- Knorr Bremse SN7000 series brakes: Optional radial position.

- Bolt on adaptable steering arm.

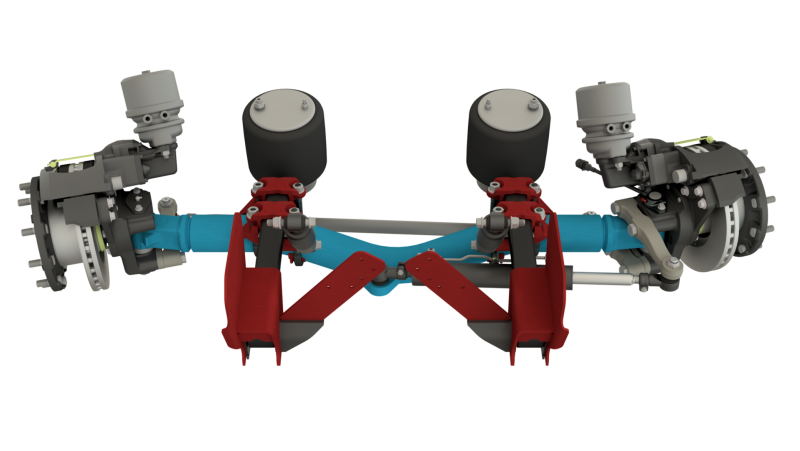

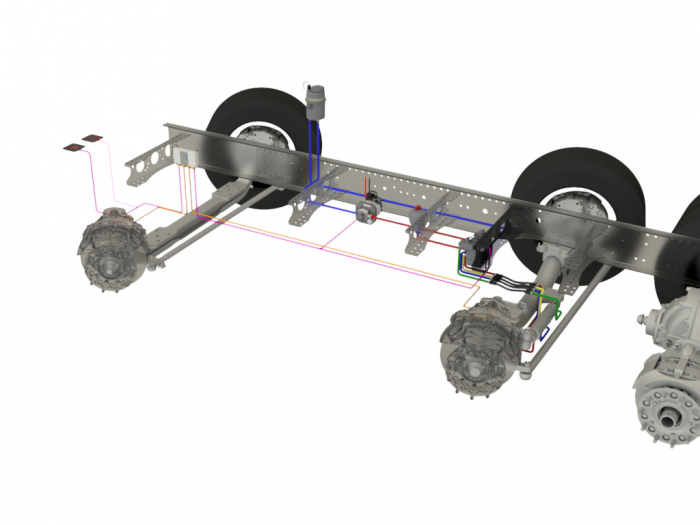

ETS

Electronical Truck Steering

Variations in vehicle wheel base or axle position is easy to set by software programming while all hardware components remain unchanged. The ETS is fully redundant and fail safe while the hydraulic cylinder is equipped with a locking-in-centre position.

The steering performance is vehicle speed related. From 0 – 25 km/h the tag axle is allowed to steer the maximum defined angle. From 25 to 45 km/h the maximum turning angle is reduced step by step by the software and at 45 km/h the steering movement stops and the axle is locked in the mid position.

The system is of the so called Fail-Safe type. When a failure is detected in the system it will enter in a safe mode (non steering) with the axle returned to the mid position and hydraulically locked with help of a constant pressurized centering system.

The steering system is fulfilling the steering regulation R79 Annex 6 and the EMC regulation R10-05.

The Power Pack consist of an E-motor 2kW.

These axle solutions are pre-assembled and in case of ETS the sensor and hydraulic cylinder are set in the correct zero-position ready for plug and play.

ETS-2:

8x2: combination of SKS and SRS

Example:

Iveco Stalis 8x2-6