Developments

MBS OMEGA RANGE

FOR OVER A CENTURY, VDL WEWELER HAS BEEN A RENOWNED EXPERT IN DEVELOPING AND PRODUCING AIR SUSPENSION SYSTEMS, AXLE-LIFT SYSTEMS, PARABOLIC SPRINGS AND SPECIAL NON-DRIVEN AXLES. NOW, THEY PROUDLY INTRODUCE THE MBS OMEGA, A MODUAL BOLT-ON SOLUTION THAT REPRESENTS THE LATEST REVOLUTION IN AIR SUSPENSION DESIGN.

The MBS OMEGA air suspension range consists of re-alignment and maintenance free 9/10 tonnes air suspension systems that have been developed in house in accordance with VDL Weweler’s philosophy: multipurpose functionality, robustness and lightweight construction.

UNIQUE CLAMPING

The air suspension is clamped around the axle using U-bolts.  The clamping is firmly held into position by an ingenious, cold-formed recess in the axle beam (Patented). The recess in combination with the counter clamping part ensures an extremely robust and durable connection, and if new fastening parts are required, the recess can easily be reused. The recess can be pressed into virtually any Ø146 axle beam on the market. This flexibility allows trailer builders and axle manufacturers to optimize their manufacturing processes and choose the ideal spring track. VDL Weweler has developed an in-house machine for pressing the recess into the axle beam. Depending on the customer’s business model, this process can occur at the customer’s location, the axle manufacturer’s facility, the trailer builder’s site, or VDL Weweler’s production facility in the Netherlands.

The clamping is firmly held into position by an ingenious, cold-formed recess in the axle beam (Patented). The recess in combination with the counter clamping part ensures an extremely robust and durable connection, and if new fastening parts are required, the recess can easily be reused. The recess can be pressed into virtually any Ø146 axle beam on the market. This flexibility allows trailer builders and axle manufacturers to optimize their manufacturing processes and choose the ideal spring track. VDL Weweler has developed an in-house machine for pressing the recess into the axle beam. Depending on the customer’s business model, this process can occur at the customer’s location, the axle manufacturer’s facility, the trailer builder’s site, or VDL Weweler’s production facility in the Netherlands.

LIGHT WEIGHT VS EXTREME PERFORMANCE (BEST OF BOTH WORLDS)

The MBS OMEGA air suspension systems feature a groundbreaking “Omega”-shaped spring steel trailing arm. When combined with other suspension components, this design results in an exceptionally lightweight system. Weighing approximately 100 kg per axle row, the MBS OMEGA systems are currently one of the lightest 9/ 10-tonne spring steel suspension systems available in the European market. When it comes to the balance between weight and performance, there’s simply no comparison. The OMEGA range stands in a class of its own.

BLADE SOLUTION

Especially for trailer builders seeking to optimize chassis production, VDL Weweler has developed the MBS OMEGA “BLADE” solution. The only difference from the rest of the range is the special chassis connection, known as “BLADE.”

This “BLADE” bracket design is a patented chassis mounting, which allows the customer to make their own sheet-metal hanger bracket plate and incorporate this in their finished chassis. As the MBS OMEGA systems are end-coated, they can simply be bolted to the finished chassis. The unique alignment feature of the “BLADE” includes a new pivot bush design, in which the classic pivot bush is eliminated and replaced by two conical shells that are clamped between the hanger bracket mountings and the conical-shaped front section of the spring steel trailing arm.The system alignment is very easy and done by rotating the hanger brackets mountings over the center top bolts. Besides being unique, the Blade-style hanger bracket design is light weight and welded in the middle of the chassis rail, meaning fewer reinforcements are required in the chassis beam.

APPLICATION AREA

The MBS OMEGA air suspension systems can be used worldwide for 9-tonne single and twin-wheel applications on and off-road, 10-tonne super-single applications globally, and 10-tonne twin-wheel on-road applications in Europe.

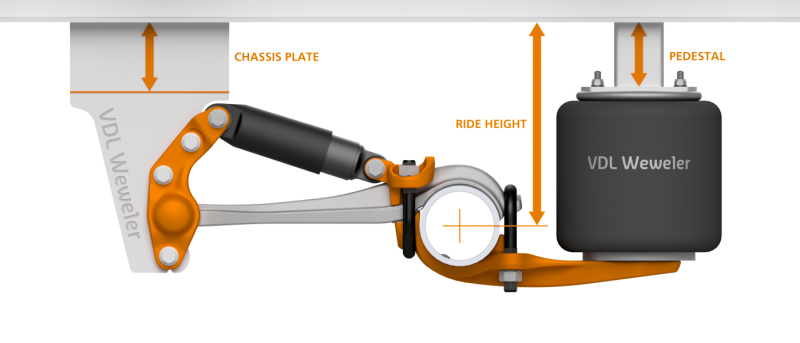

RIDE HEIGHTS

Regarding ride heights, the MBS OMEGA range offers options from 180mm to 550mm using low, standard, or high versions. The entire range consists of just two trailing arms, various hanger bracket heights, shock absorbers, air springs and tailends.

For the “BLADE” version, height variation comes from adjusting the length of the chassis plates and pedestals.

CUSTOMER SPECIFIC

Customization is possible for the MBS OMEGA air suspension systems, based on specific customer requirements.

AXLE LIFTS

VDL Weweler has over 40 years of experience in developing and producing axle lift systems. These systems are designed to lift air-suspended axles, resulting in reduced tire wear, lower fuel consumption, and decreased maintenance costs.

For all MBS Omega variants new lightweight patented axle lifts are designed.

Download MBS Omega Flyer